it’s been so long since I just did a routine ‘page report’ that I almost forgot how. Anyway, the plane is effectively grounded since I’m at 25 hrs on the Hobbs, so—despite being a beautiful day—I decided to get to work on finishing the plane by doing the wheel pants. I also have a bit of a deadline as I need them done before we go to get it painted next week.

The current plan is to get the engine inspected on Friday morning and take the instrument panels to the painter in the afternoon. He will take off the spray paint (that’s already flaking) and do a nice carbon fiber overlay. I’m out of town next week, so that works well. While the panels are being done, I’ll start on the annual condition inspection. That should be signed off in early December. I have 1 or 2 flights to do to finish the Product Acceptance Procedure which I will do and then deliver the plane to Marion for paint. After getting it painted and re-assembled, it will be very appropriate to sign it off from phase I!

Anyway, back to the present.

Back in the summer, I had finished sanding the front shells to mate well with the rear shells. It took much longer than expected, and was surprisingly difficult. One of my hangar neighbors has a new-to-him RV7 (?) which is gorgeous. I decided that i may be getting a tad anal about trying to match sand the shells, so I went over and looked at his wheel pants. They have a bit more gap than I do, and his plane is perfect, so I stopped sanding.

Once again, I read the instructions until I understood them (cue the minor key violins) and proceeded with confidence. I drilled out the little dimples where the screws will attach the wheel fairing brackets. Damn. The dimples only are useful if you happen to have sanded the shells exactly as designed. See paragraph above. It took a while to figure out what to do. I didn’t want to just drill again too close to the holes, so I ended up mixing up some flox and filling in the holes, then overlying that with some fiberglass. That was about 2 months ago.

Today I finished fitting the shells together with tape and drilling the 9 #40 holes around the ‘equator’ and clecoed in place (from the inside.) I screwed the wheel fairing attach brackets into the rears, then used a light to shine through the front holes and match drilled them. Viola!

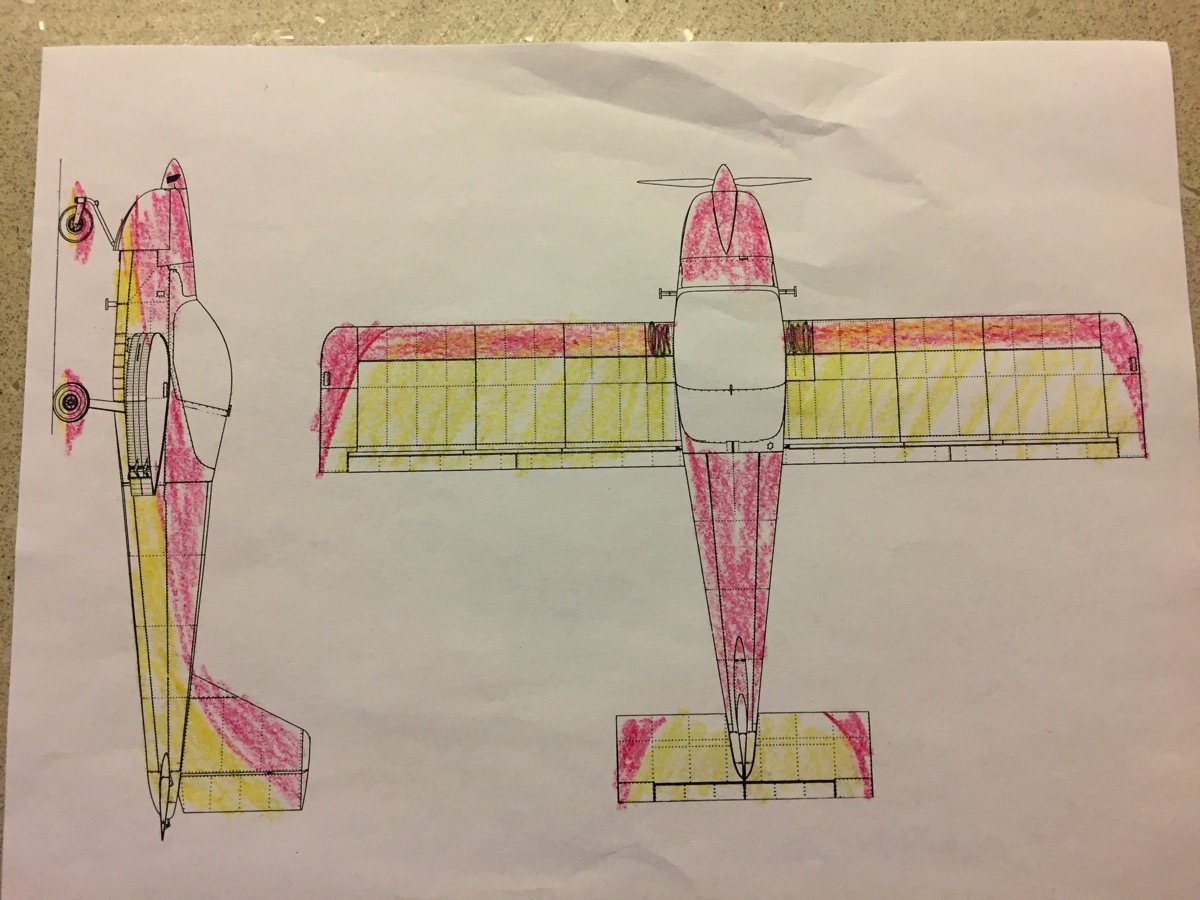

Match drilled Main Wheel Fairing

With the bright light shining through, you can see the fiberglass repair showing through. It’s quite invisible without the internal light, much less with paint.

The next page was to mark and cut out the locations that the gear legs will pass through. I laid down masking tape and double checked all measurements before making short work of it with the dremel cutting disc and small sanding drum. Alas, I ran out of time and didn’t get to proceed to the next page. Next time!

Main Wheel Fairing with leg cut outs