Well, it was fun to finally get back to “real work” and be done with the fuselage cradle. This page was notable for the comic relief of watching me attempt to fit the Left 1207C bulkhead onto the Right side of the plane. After getting most of the holes to cleco (reluctantly) I finally remembered the dictum of “if something doesn’t go together right, you’re not doing it right.” I let myself get that far because I was a bit distracted by the instructions comment to flute the pieces so they fit, thus I expected them not to fit when I started. Turns out the fluting was quite minimal (or, it was not minimal but I am educated enough to have made a good estimate on my first pass.)

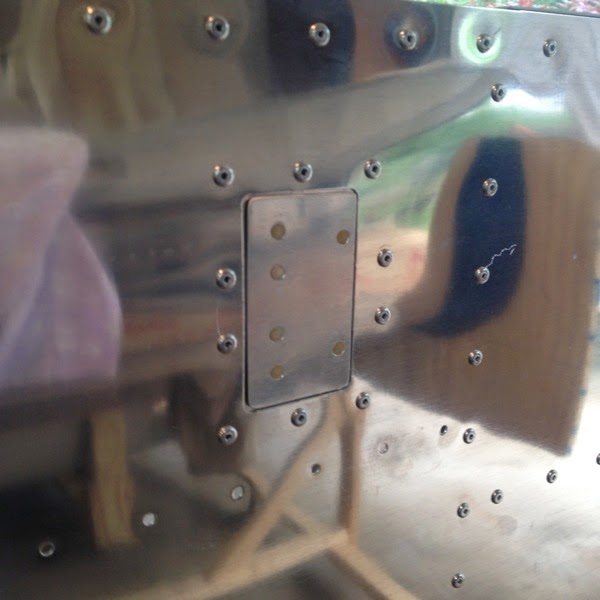

On the other hand, not everything goes according to plans... Take a look at the bottom of the Left Bulkhead Channel. How many holes do you see? I see two. Note the excerpt from The Book:

bottom of Baggage Channel

Excerpt of page 24-05

Note how the instructions call out 3x SB375-4. I installed 1 SB375-4 and 1 SB750-10. There are a couple of threads on VAF regarding this, but no definitive answer from Van’s (e.g., Scott, the Van’s employee who appears to have adopted the -12 as his personal responsibility.) I’m going with the prevailing view that the design was changed but the drawings did not. Watch this space...

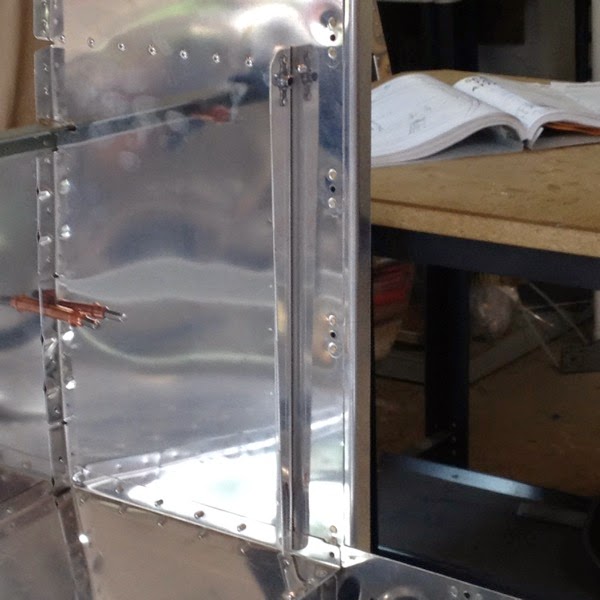

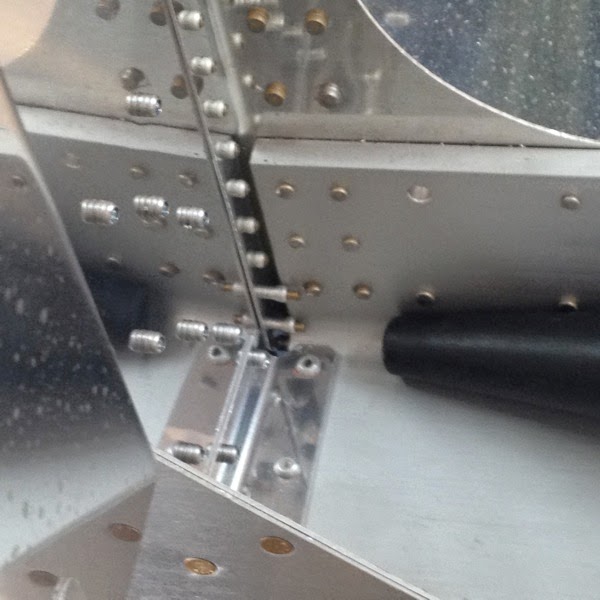

Back to the good news. Everything else went together as drawn, I got some practice doing squeeze rivets, countersunk rivets, regular rivets and ended up with a nice bit of visual progress.

F-1207 Bulhead

Here’s the aft end of the fuselage. The longerons are still dangerous, so they still get their little orange safety balls. I didn’t capture the roll bar and roll bar attach bar which stabilizes the top of the 1207, but you’ll probably see that detail in future posts.