Sept 5, 2014:

This page was originally posted prior to completion, because I was just so pleased with the progress that I couldn’t wait.

Initial fitting of the Canopy

The canopy has been placed for the first time! I’m supposed to trim it to fit, and that’s got me a bit uptight, so I’m taking my time and letting everything settle in my mind before proceeding. On the other hand, it’s a mile stone worth pre-publishing. More to follow...

Sept 11, 2014

Here’s more. I’ve been pretty busy this week, but haven’t finished fitting the canopy. The Book calls out that I have 1/8” in gap from the front of the canopy to the edge of the instrument panel. I’m not able to achieve that close of a fit with the canopy frame clamped to the roll bar as per The Book. If I release the clamps, it (the canopy) moves forward about 1/2” and is exactly where the book calls for it. The Book says I can relax the clamps when I’m drilling the rear holes, but I’m not at that part yet, so I’m not confident that relaxing the clamps is a kosher maneuver.

Too much gap.

Note that the canopy edge is essentially overlying the top of the front bow. There is, at most, 1/4” between the contact line and the edge of the canopy. If I drill and rivet here, I’m pretty sure that I’ll break the leading edge of the canopy.

I decided to add all of the other stuff to the canopy attachment process, particularly the latching mechanism. Specifically, I will remount the canopy with the latching mechanism in place and measure the front gap (1) with clamps in place, (2) with canopy latched closed, and (3) without any restraints. I’ll take those numbers and fire off an email to support at Van’s and get back to you on this page with the results.

Personally, I’m hoping that I have acceptable measurements in condition #2, since that’s “final configuration” and I’ll be cleared to do final measurements and drilling. (that is, as soon as this cold front passes and the temps warm back up into the 70’s or 80’s.)

Sept 21, 2014

Slow and steady wins the race.

I got some advice & feedback from VAF, but nothing definitive. I sent a couple of letters to Van’s but still ended up calling them to talk about it. Joe, in Support, eventually opined that about 1/2” of plexiglass ahead of the forward bow would be enough to not have to worry about being too close to the edge. The 1/4” gap specified between the canopy and the instrument panel appears to be un-important, as he had no real idea where it came from, whether it was a minimum or a maximum, etc. He said the big concern was that the canopy wasn’t too close to the edge, as it would catch and prevent the canopy from opening.

I did discover that if I put the canopy on the frame, opened and closed it, the weight of the canopy itself did a nice job of helping to align itself sufficiently in the fore-aft direction. I did take advantage of the permission to elongate the latch hole by its 1/8” allowance, but that was about it.

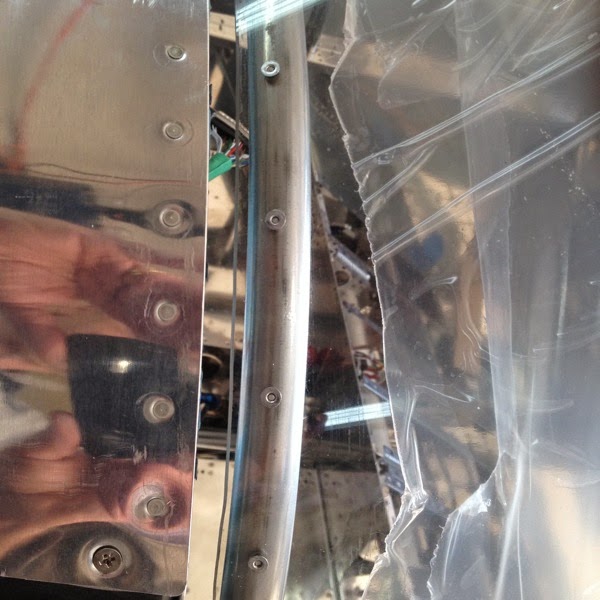

Contact Line of Canopy to Front Bow

I had been using blue painter’s tape to prevent scratches, and in all of the previous test fittings, I had a very hard time seeing the contact line. I used regular masking tape for the final trial fit and was pleasantly surprised at how well the contact line showed up.

Holes drilled in front of Canopy & Front Bow

1/8” gap from Canopy to Frame

I got all of the holes drilled last night, including final drilling to #27. It was a race, as that was the only day off when it was forecast to be warm. Temperature in the garage was about 77 °F. I used some modified bits and didn’t have a single crack, including one hole (L side, most forward hole) that ended up being right on the edge.

Acrylic Bits

These are the home made acrylic drill bits, #27 and #30. I found this technique after much searching (and soul searching.) Take the bit you want to modify (typically a dull one) and chuck it into a reversible hand drill. Run it in reverse against your grinding wheel to make a nice, sharp point of about 60-65°. These really end up being scraping bits instead of cutting. They melt through acrylic, but really make a mess gouging / punching through thin aluminum, so you’ll have to do some cleaning up after drilling through both acrylic and aluminum sandwich.

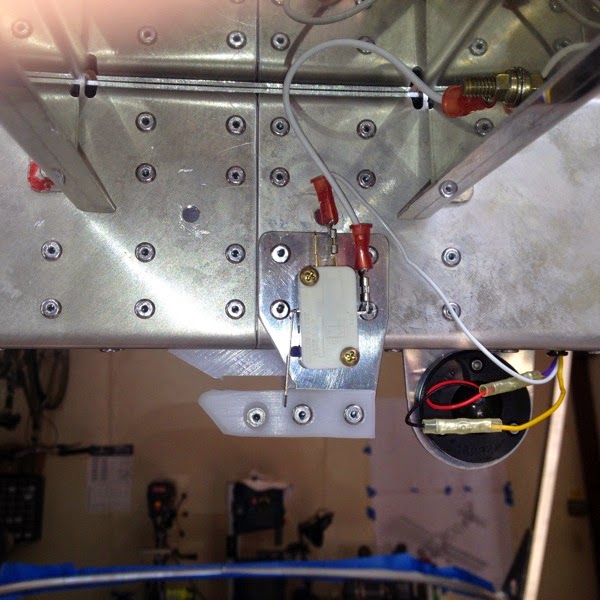

Guide Plate

Guide Plate