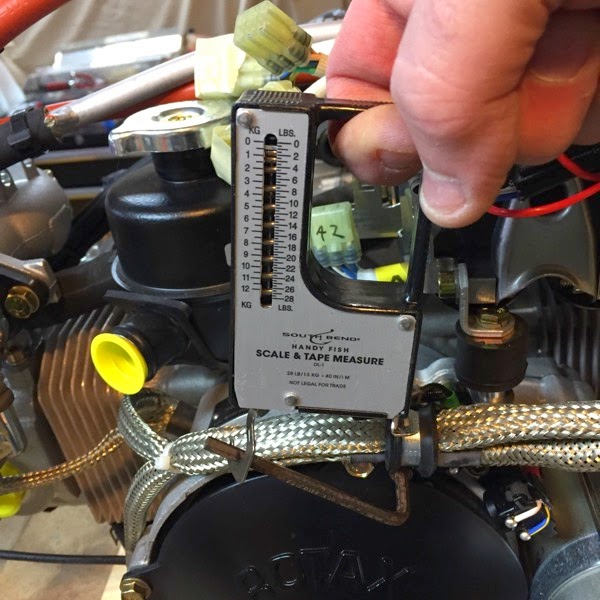

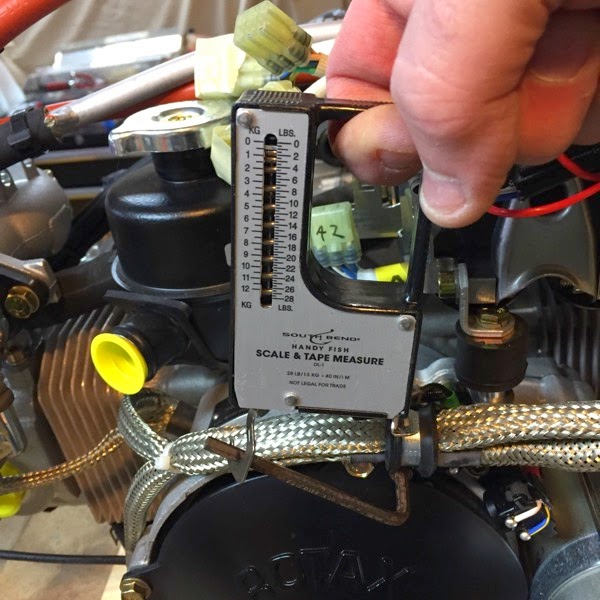

I ended up buying a bunch of tools today. Below is a picture of a make-shift torque wrench. I have a large collection of misc allen wrenches which I’ve been using on the Rotax. Step 1 of this page states to torque the bolt to 55 in-lbs, but I only had the allen wrenches, not yet having purchased my new shiny (expensive) metric hex socket set. I used the same fish scale from the front wheel, measured out 2.5” on the allen wrench and pulled until I got about 22 lbs on the scale. Later, I checked again with my new tools and found that I came up to about 60 in-lbs torque. not too bad for a Macgyver...

make shift torque wrench

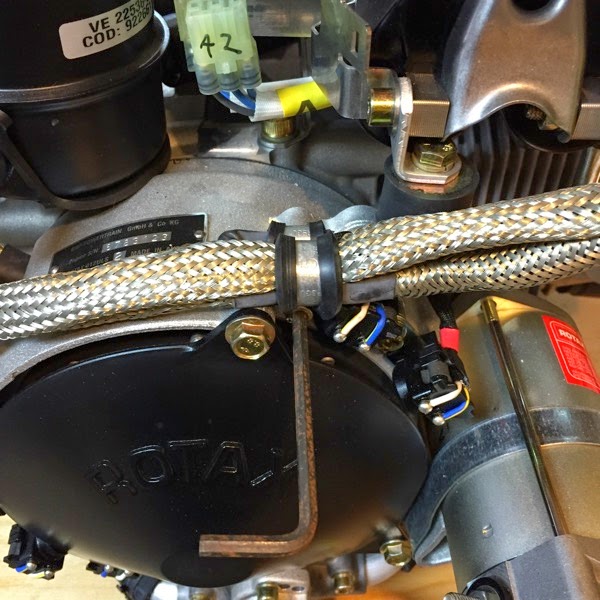

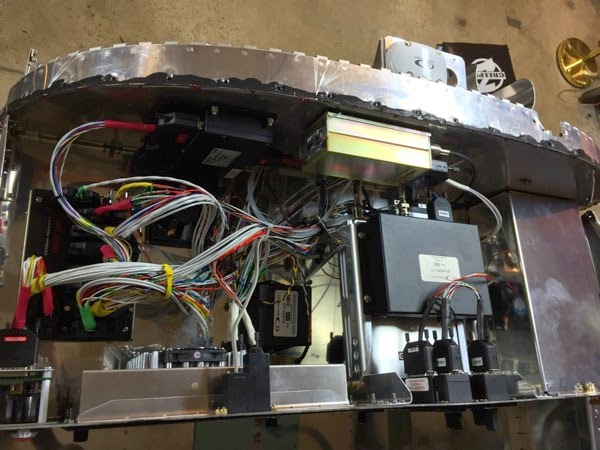

Generator / Flywheel Assy

It wasn’t hard to remove the plastic cover, but it was surprisingly hard to move the flywheel to the proper positions to use feeler gauges to verify the gaps on the magnetic pickup coils (the 5 black ‘buttons’ with the blue & white wires). The flywheel moves 2.43:1 relative to the prop flange. The prop flange gets rotated with a couple of generic bolts leveraged with a large screwdriver. Despite removing spark plugs from the cylinders, there’s a lot of torque needed to rotate the engine. I was very surprised, as I recall being surprised the other way with how easy my Lyc IO-360 rotated when there were no plugs installed. I’m hypothesizing that the difficulty in turning the Rotax is due to the built in generator (as seen in the picture) that will always resist rotation to some degree.

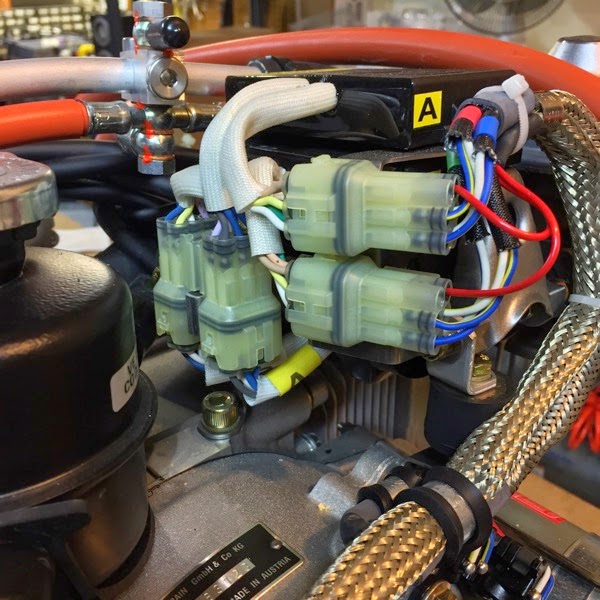

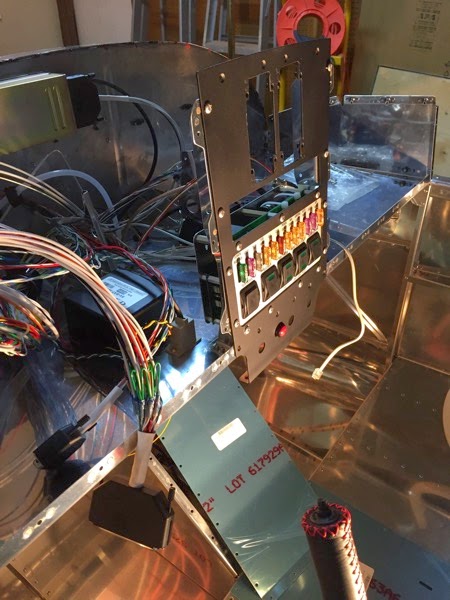

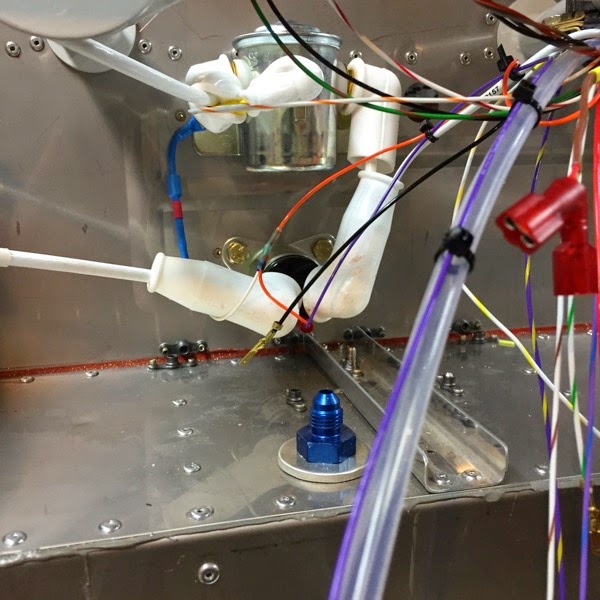

Intake & Ignition removed from engine

This feels like surgery. I’ve disconnected the ignition system and then unbolted the intake manifolds, then flipped them up and over on their back, laying on top of the prop drive unit. You can see the open ports into the cylinders (before I taped them up.) Next step is to move the black 4-legged octopus on top. That will give me a wide open view of the top of the engine so I can start fitting the cooling shroud.