What a royal pain in the pa-tootie! It took forever to get this page completed. The two biggies were my work schedule (lots of unwanted overtime) and the fact that it was not possible for me to fit the ends of the control rod assembly into the forks of the control sticks. I had the fuselage up on its R side and was working in relative comfort. Unfortunately, I couldn’t see up into the L seat area because my trifocals have the close vision lenses on the bottom and I can’t crane my neck that high up any more. I couldn’t see down into the R seat area because..., well, I can’t remember what was in the way, but it was.

The end of the control rods require two steel washers to be interposed in-between the forks of the control sticks. Try as I might, it wasn’t possible to fit them in. To make matters worse, at one time I dropped the pushrod assembly from the L side (upper) and it fell all the way through to the R fuselage wall. In the process, one of the steel washers disappeared and I spent over a week searching for it. I had reluctantly concluded that it may have been flung free of the aircraft into the garage. Luckily, I found it when working on the wiring harness re-work, so I no longer have to worry about a loose foreign body floating around in the belly of the beast.

Others on VAF confirmed that this is a problem. One gentleman said that he had to jury rig a spreading apparatus to open up the forks a bit. Another guy was able to remove the control sticks, attach the rods and somehow snake the contraptions into place. I did end up removing the control sticks (and having to rewire the PTT harnesses in the process) and finally got the damn steel washers in place. I didn’t have to make a Rube Goldberg spreader, but I did use a pair of pliers as spreaders to get the washers in place. I wasn’t able to snake the stick and rod assembly into the proper place, and even got it stuck to the point that I couldn’t get it back out for half an hour.

I finally elected to unscrew the control push rode from the bearing on the end, re-install the control stick and then re-thread the rod onto the bearing. To keep the length “just right” I used superglue on the AN316 jam nut to keep it in place. After I got everything installed, the sticks weren’t quite parallel. I locked the mixer in neutral (see pg 32-09) and noted that the R stick was a little too far to the right while the L stick was vertical. I disconnected the R pushrod from the mixer, backed out the bearing stud by 1 revolution and that brought the stick to vertical nicely.

Last, but not least, I found that the control pushrods rub against the AN365 lock nuts holding down the front control block. They only make contact with the stick full back and full roll (either direction.) I’m waiting for some low-profile lock nuts to replace the ones currently in the kit. If that doesn’t fix the interference, I’ll grow more grey hair and figure out something. I’ll also post a query to VAF to make sure that I didn’t do something wrong.

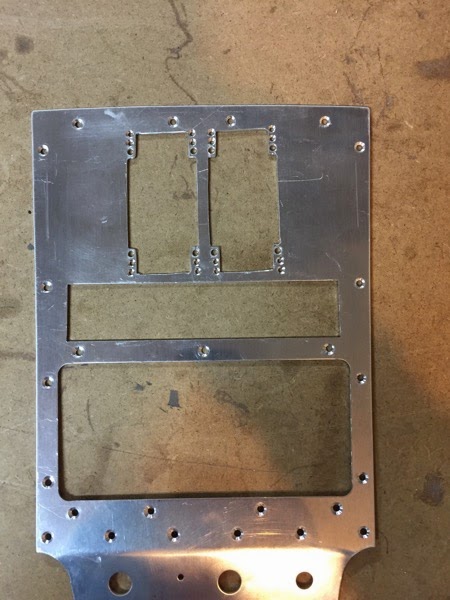

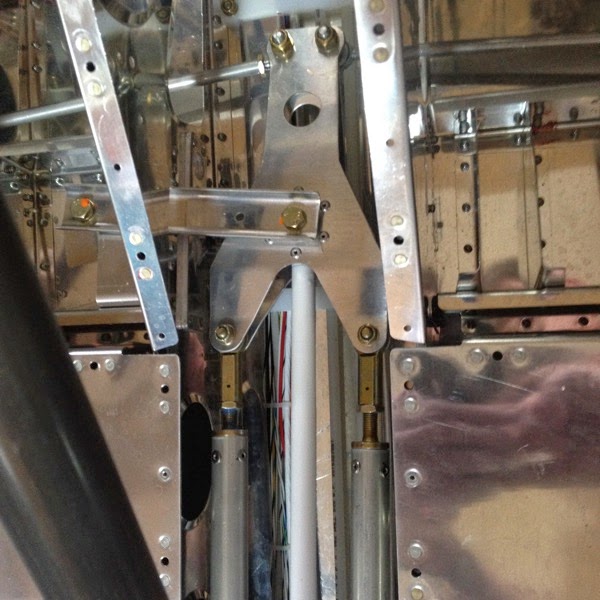

Control Stick Push Rods attached to Mixer

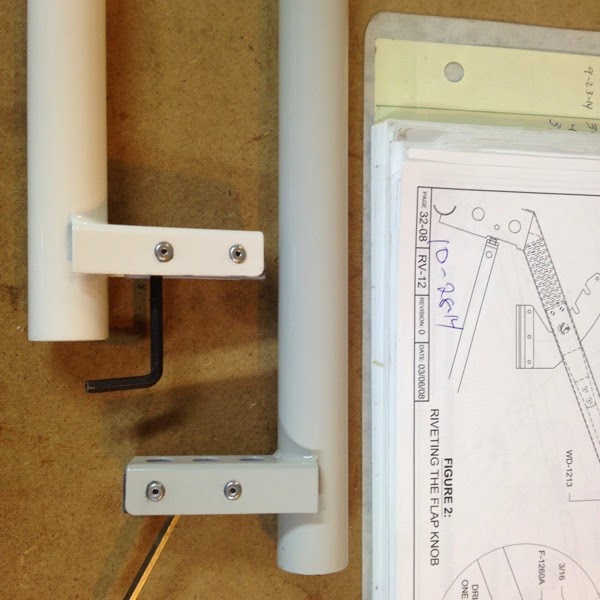

Push Rod connected to fork at bottom of Control Stick

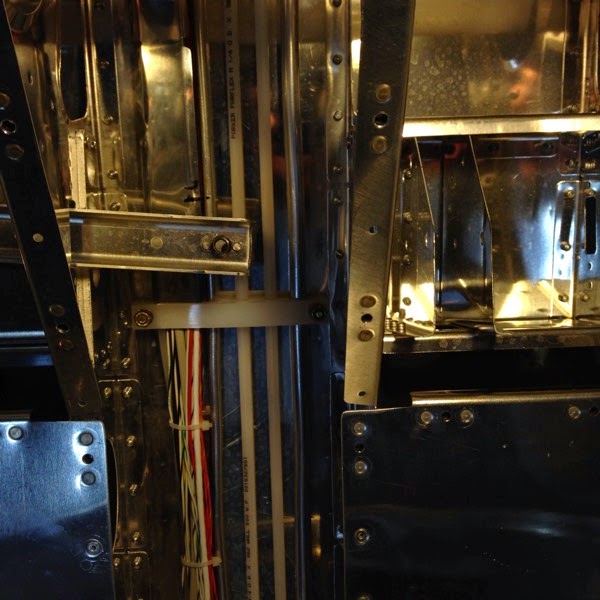

Push Rod rubbing against lock nut

---------------------

Addendum: I discovered why the push rod was too far forward and rubbing against the lock nuts. I’m not yet used to the way this plane flies, and made an error with the use of the flap control rod. I had pushed the flap control rod all the way down, past the detent for 0° flaps. This would make flaps slightly reflexed (e.g., negative flap angle) and is not an approved flight configuration, thus the designer had no need to verify that the internal parts would not contact each other. When the flap handle is pulled up slightly, it pulls the push rods aft just enough to not contact the lock nuts (and makes highly loud “thunk” in the process!)