This post is a bit different. My mentor is not able to travel to Westerville to see my project for supervision. He requested some photos of my worst work. Here they are...

Problem: Cleated rivet in rudder upper hinge assembly. See entry for 07-03 (July 2013) for a description of the creation of this problem.

Solution: Obtain expert opinion regarding the known cleated rivet. Worst case remedy is simply to purchase a new rudder. The time in de-riveting the entire structure wouldn’t be worth the cost of new material. Furthermore, I made the problem in the first place by attempting to drill out rivets.

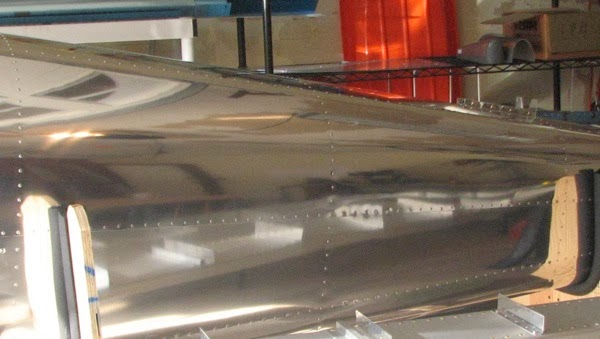

Problem: Failed to deburr edges of factory pieces: This photo doesn’t show it, but there is a rough edge all along the upper skin. It didn’t occur to me to deburr pieces that had been cut at the factory, but now I know.

Solution: I have ordered a 2” scotchbrite wheel. I have a Dremel tool and some scrap Al. Place the scrap about 1/4” from the edge and use the wheel to deburr the edge. The scrap will prevent scratching of the adjacent skin.

Problem: On multiple occasions, the predrilled holes were too small to accept an LP4-3 rivet without either final drilling #30 or some ‘encouragement’. The photo below shows what resulted from being too firm with the rivet instead of taking the time to final drill the hole: you can see an unwanted conical dimple around the rivets.

Solution: Take the time to final drill the appropriate holes. I also acquired a #30 and a #40 reamer and will see which has a better edge, since it is often impossible to deburr these holes that need finishing.

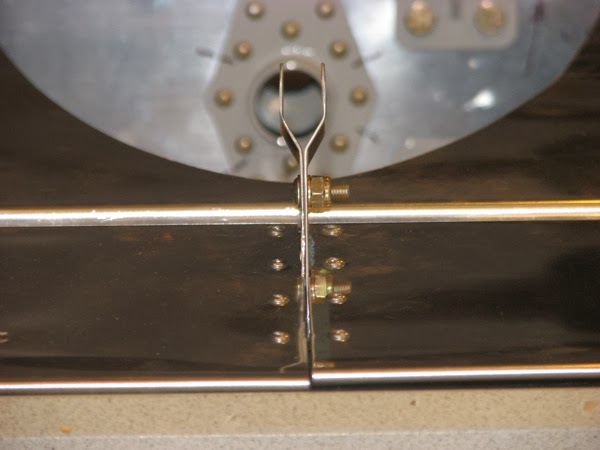

Problem: The Book called out 270AD4-4’s at 10-06 #6, which I know I placed properly, only to find that they had cleated. My analysis is that the -4 is too long, but that there aren't any 270AD4-3's. I ground down some -4's to about -3's and they installed very nicely on the other side. I drilled out one of the cleated rivets without any problem and installed a modified rivet. (These were checked with the rivet gage and met spec.) The other one (as shown on the right in the photo below) did not drill out cleanly and I was left with an ugly, out of round, nasty looking hole.

Solution: Consulting The Book, the remedy called out is to drill with the next size up and use a larger rivet. I don't have any AN270-5's, but had recently purchased a spare rivet puller with an assortment of pop rivets, including some 5/32's, for just such an occasion. One of those was installed as you see above.

Problem: The trim tabs (AST’s) are not flush with the trailing edges of the horizontal stabilizer.

Solution: Investigation to find out where the discrepancy is arising. I will remove the AST’s and see if they are actually flat along the trailing edge. I also need to verify that the HS-1217 aft skins are also flat on either side of the stabilator. While the tabs are off of the stabilator, I will also lightly file the piano hinges of the R side, as it has palpable binding and squeaks when moved.

If no solution presents itself, I will correct the mis-alignment by reinstalling the trim tabs, but not bolt them together at the control horn. The edges will be held in best possible alignment and the bolt hole in the control horns will be match drilled with a larger drill and secured with a larger bolt.

Problem: The photo shows the effect of not establishing a good bore-sight down the predrilled hole. I was actually at a 6° angle and drilled through the surface of the aluminum extrusion. Unfortunately, I was not looking at the extrusion itself, as I had turned the spar over to improve access. (I don't know if watching it would have made much difference, but I probably would have caught it earlier and been able to re-align the drill.) The tap has been re-inserted for this photo and is just barely visible at the lower end of the hole.

Solution:

So far, I have identified 3 paths to pursue. Easiest (and therefore of greatest suspicion) is to ignore it and use the tie down as if nothing happened. The threads are intact along the upper (as oriented in the photo) and lateral walls of the long axial hole, but probably non-existent on the lower edge of the hole directly under the unwanted opening. As a total WAG, I guess that there's a 30° arc x 1/2" where there are no threads. Is that lack of contact enough to compromise the strength of that bolt? (What is the function of that bolt, anyway? I'm further guessing that its to suspend the wing in maintenance actions.)

2nd option is to ignore it completely. That is to say mark the tie-down as InOp and never use it.

3rd option is to re-drill with a larger bit and re-tap with larger threads. To ensure good strength, I would tap 2" to obtain a full inch (original spec) of completely engaged threads. Will there be sufficient aluminum to accept the larger bolt? Hmm. Sounds like I need an engineer.

Problem: The W-1212 hinge assemblies developed a gap at the edge of the bearing.

Solution: I already wrote to Van’s and submitted the above picture. I was told that they were serviceable and did not need to be remade. I also received a hint to prevent future occurrences (prestress the distal ends inward slightly prior to riveting.) No further action required.