Now, I’m really annoyed. Here’s what the tank looked like after I pried off the top (before I cleaned up all of the debris of cured ProSeal.)

inside of fuel tank

I sealed up the left lower front corner and the right upper front corner from inside & outside. I resealed the top. I took it home and put in in a small bathroom with a space heater to keep temps above 80 °F x 48 hrs to help accelerate curing. I took it back to the shop and filled it to overflowing with gas. There was a much slower residual leak at the right upper front which I then re-applied external PS.)

OK, now everything is looking good. Tank gets drained again, re-installed again. Tank gets filled, didn’t see any leaks. Spent a few hours doing taxi tests, ,tweaked carbs’ sync, did a static run up (5300 RPM), did brake tests, and aligned the digital compass. (Also discovered that the heater door doesn’t close all the way. Very effective heater, especially in a 75 °F day!) All in all, it was great progress. I seriously considered 1st flight the next day.

misc engine tests

Today, I opened the hangar to discover fuel on the floor! Sure enough, there’s gas on the inside of the plane. Last time, I was very fast to defuel the plane to stop the draining. Today, I took 5 min to really see if I could find the source. As I recalled—and confirmed today—the leak appears to be left (medial) rear lower corner since there was gas on the inside of the baggage compartment, plus a bead of gas running down the left lower edge, thence to the outside of the fuel feed / fuel return and a mess all over the inside belly skins. Upon tank removal, there was no gas staining on the right (outboard) side at all.

Now I’m stumped. A full fill test x 2 hrs showed no leaks. I know I triple checked the left lower rear corner because I suspected that was the source when I pulled it last week. The only thing that came into my brain was “what’s the difference between being in the plane vs. on the bench?” The answer is “mounting.” In the plane, the tank is suspended by 3 bolts (1 AN4 at the back; 2 modified AN3’s in the front.) This puts the floor of the tank in tension. On the bench, the weight of the tank is pressing down on the floor, so the floor is in compression.

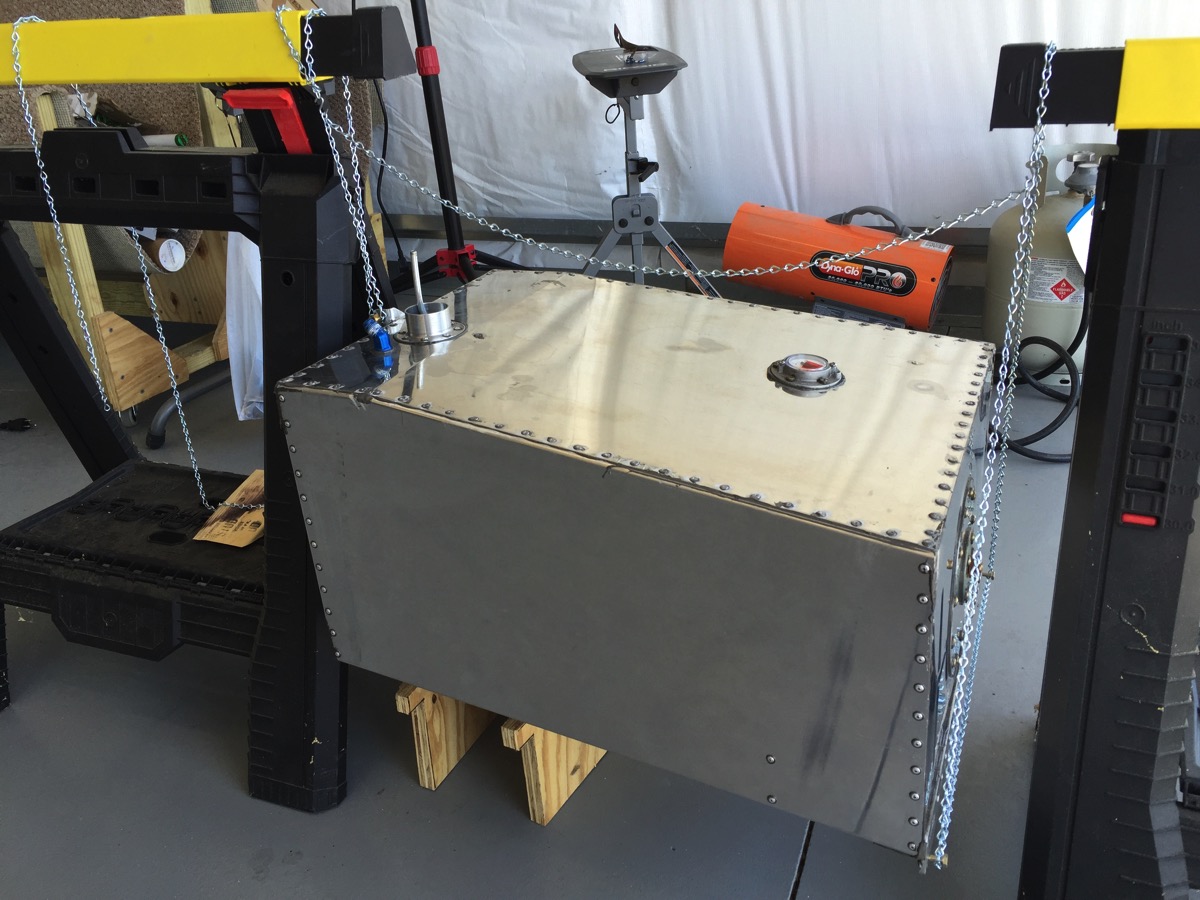

I rigged up a quick suspension cradle with some light chain and a few bolts.

gas tank suspended to emulate in situ mounting

Viola! After 7 gals of gas were added, there’s a clear leak, right where I expected: left rear lower corner.

leak #3 at left rear lower corner

Now, what to do? I’ll call Van’s in the morning to discuss getting a new tank. With 3 leaks, I really don’t feel I can trust this one. On the other hand, I want to get airborne as quickly as possible. I suppose I can remove the face plate of the tank and reach back there to clean and re Pro-Seal from the inside as well as the outside and hope for the best. (The extra time to do that doesn’t bother me, since there’s a 48 hr cure time.) On the other hand, if Van’s will swap me a tank quickly (unlikely, as I don’t think they have any stocked), that would be great. I’ll find out tomorrow.

No comments:

Post a Comment