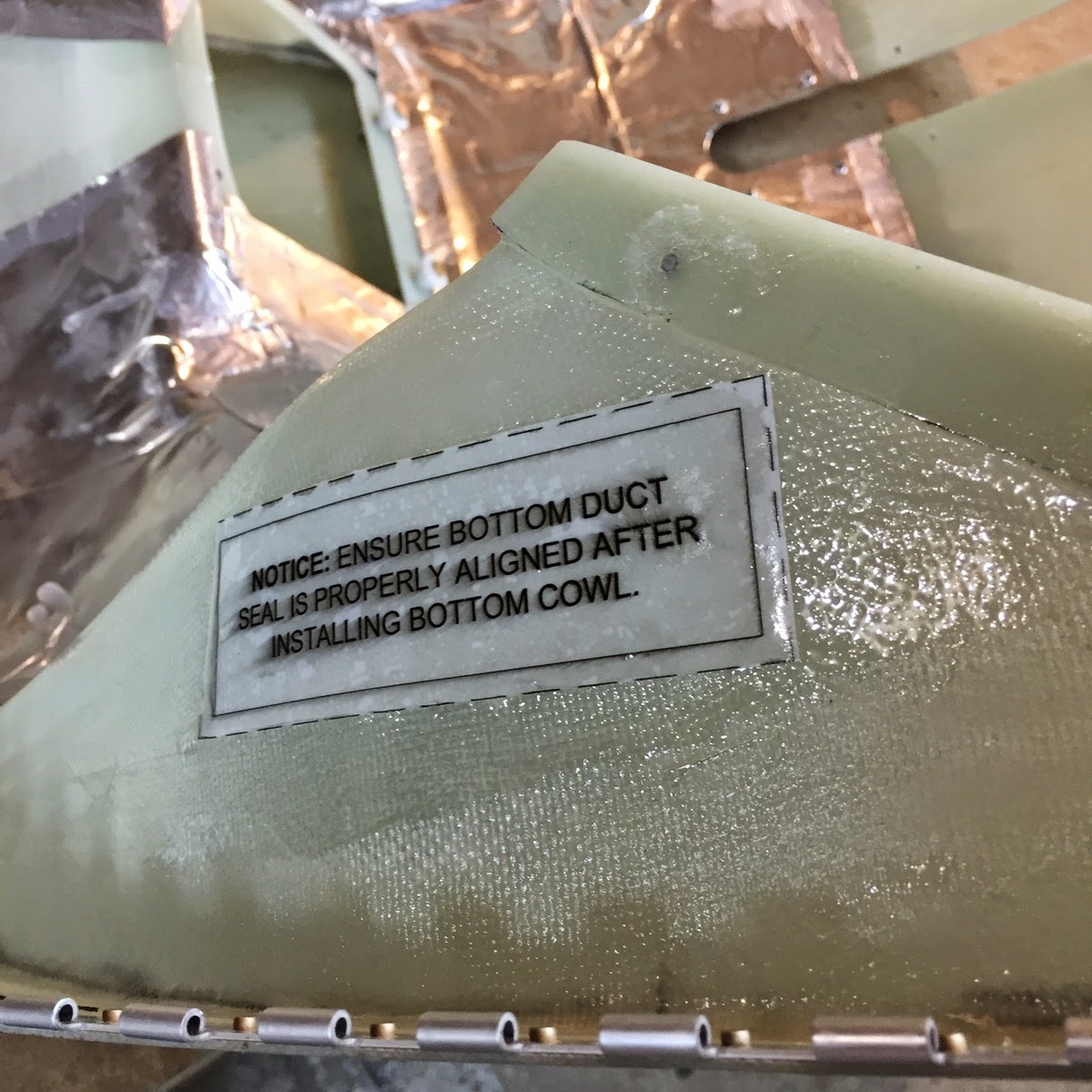

This was another new experience that I had been putting off for about a year—working with wet fiberglass. I purchased a fiberglass “beginner’s kit” from Aircraft Spruce last year when I realized that I would need to do some epoxy work on the wing tip lights (still not done, BTW.) I read & read & studied, and it went very well. I didn’t get any pictures of the wet layup of the cooling duct inside the cowl because I forgot to snap them before installing the cowls on the plane while the epoxy cured. The representative photo that you see below is looking at the duct bonded to the lower bowl’s “mouth” after I used a touch of floxed epoxy to fill in the transition. It went really well and did not take much at all. The Book said to use bondo if there was a small crack, but I didn’t want to go out and buy bondo when I had perfectly good floxed epoxy sitting in the freezer from the night before.

Cowl to duct interface

final touch!

No comments:

Post a Comment