Busted #12 drill bit

I broke a drill bit trying to get at the innermost pair of holes on the control column. It took some hunting to find a replacement (without waiting for mail order). In the process, I ended up buying a right angle drill attachment, but it uses a hex drive and doesn’t have a chuck, so my new bit won’t fit. I was belatedly surprised to discover that the new bit did pass through the holes, so I must have gotten through on the pass that broke the bit. I used a Dremel tool on a flex shaft to clean up the ragged edge of the hole. It’s slightly larger than called out; I may have to use something to increase the local diameter of the bolt that will eventually go in there. After all of the holes were drilled out, I was concerned that having removed the powder coat (as per the instructions) that would leave the steel column susceptible to moisture in the air and possibly rusting. I inserted AN3 / AN4 bolts and lubed them with Beolube in order to coat the exposed edges with oil. Hope that works.

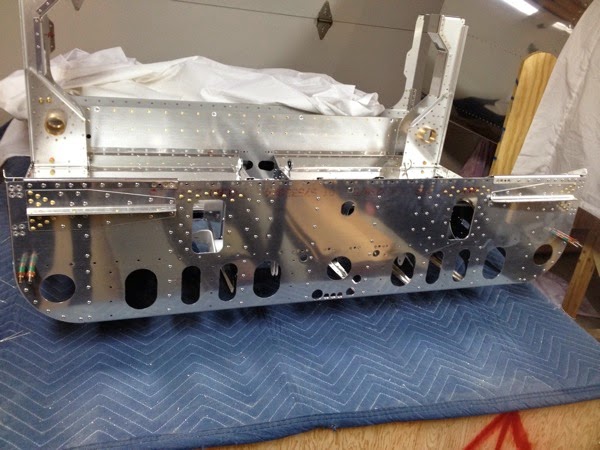

Installed F-1203 Bulkhead

Installed Seat Ramp Floors

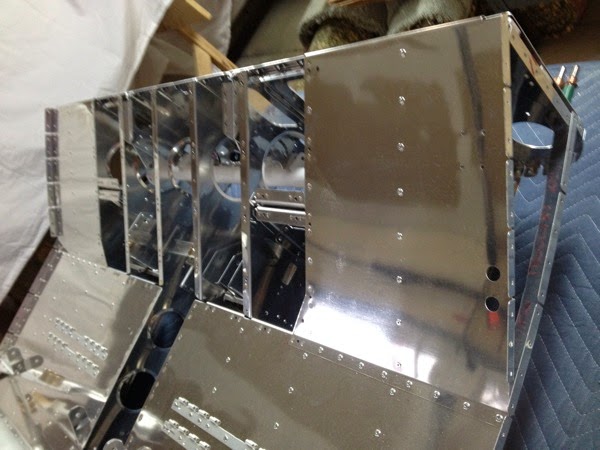

Note the control column resting on the bottom of the lightening holes. As predicted by the instructions, it was a tight fit to negotiate that column into the proper location, but it wasn’t a show stopper.

Control Column

Technically, this picture belongs on the next page, but it was such a logical connection that I decided to post it here, while it was still fresh in my memory. The bolts are centered with 2 960-10 washers just inside the steel ears. The book said I could use some tape to get everything aligned, but I used a thread to ‘fish’ the washers into place. It worked quite well, actually. I ended up doing 3 installations. The book said to use 960-10’s or -10L’s, as needed. I used one of each on the first pass, but those were a bit loose and it needed to be replaced w a pair of -10’s. Not bad at all. Since I’m working 6 consecutive night shifts, I needed to get to bed so I didn’t do any more work today.

No comments:

Post a Comment