Much creative brain power went into the accomplishment of this page. Taking things out of sequence, let’s address the water pump tubing issue first. I simply was not able to figure out the 3-D puzzle of negotiating the engine mount into place without seriously injuring the water pump outlets, despite what The Book said. I also found that there were 2 or 3 other methods that had been discussed on VAF and also by Dave Gamble in his epic books of the assembly of N285DG (“Schmetterling Aviation, The Building of an RV-12, Vols 1-3”). I tried all of those and realized I was getting dangerously close to frustrated and liable to bend/break something. That’s when I noted that the good German engineers had used simple reliable techniques for assembling the water pump. 7 bolts later, it comes off easily. Even better, it went back on just fine. IMHO, The Book should simply tell you to take the damn thing off, along with the carb’s and cooling system.

Water Pump without exit housing & exit tubes

While we’re at it, let’s look at some other details in this picture. Note the small piece of wood under the water pump. It’s actually under the oil drain banjo bolt and is holding up the south end of the engine. In the background of the picture, you can see two metal plates that are bolted to the plywood that the engine is resting on. Funny thing, those plates. The engine arrived in a crate with those metal plates attached to the inferior engine attach points and to the bottom of the crate. To make a stable platform for working on the engine, (Big) Nick helped me remove the engine, cut out the bottom of the case and then rebolt it to the wood.

As I prepared to start fitting the engine mount, I realized my problem: the engine was currently being supported by the very locations that I was planning on attaching the mount. I was able to re-position the plates to only bolt to the front end of the engine by putting the wood (which I trimmed to desired thickness) and then moving one plate at a time to just the front. Later, (Little) Nick and Lada helped me lift the rear to put a larger wood block under it to make clearance for the mount. Long story, short: I still have a pretty stable support for the engine, as it has positive support laterally as well as longitudinally.

Engine Mount bolted to Engine

Nice close up of the M10 bolt holding the mount to the engine, complete with a drop of lacquer for detecting any backing out. There were some cases of this bolt working its way loose and this was later determined to be due to using the standard torque of 26 ft-lbs instead of the (very well hidden) 30 ft-lbs specified by Rotax. Of note, Rotax documentation everywhere says to follow the aircraft mfr.’s instructions, and Van’s says to follow Rotax. The specification in question is found buried in the Illustrated Parts Manual For Rotax Engine Type 912 and 914 Series. Why this value would be buried down in the parts manual is beyond me. Anyway, lots and lots of discussion on the use of Locktite and of Nordlock washers. I even found a reference that showed how the traditional spring lock washer can actually promote loosening in some applications. I think I like the Nordlocks more than Locktite.

side view of engine with mount

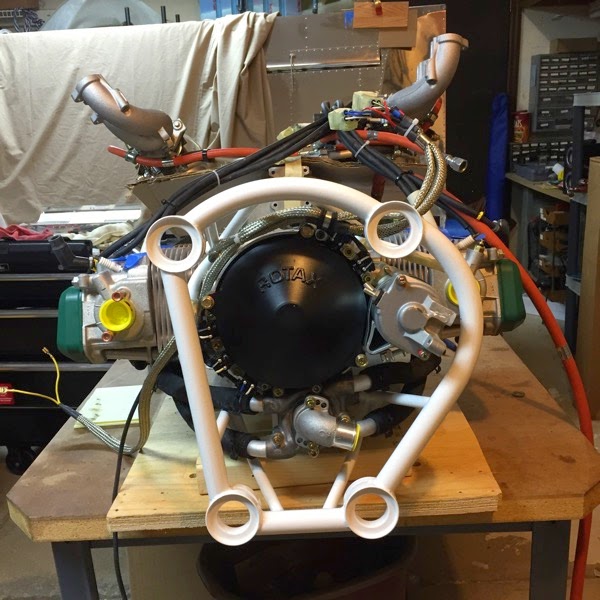

rear view of engine mount

The side picture shows a pretty ugly collection of loose tubes & stuff. Ugh. I used to think that the engines didn’t look nice to begin with, but now I’ll appreciate them more when everything is attached properly. The rear view is nicer, and a bit more symmetric except of the weird bulge and the starter motor hanging over on the right. Oh, well. Aesthetics are not the important part here.

No comments:

Post a Comment